Hot Melt Polyester Strapping A Strong Economical Alternative for Waste Bale Transport

In the evolving world of waste handling and recycling logistics, the choice of baling materials can significantly impact efficiency, safety, and cost. One material gaining widespread recognition for its performance and value is Hot Melt Polyester Strapping. Known for its high tensile strength and resilience, this strapping solution has become an increasingly popular alternative to traditional twine or rope, especially during the transportation of compressed bales.

Hot Melt Polyester Strapping—sometimes referred to as “hot melt cord strapping”—is made from high-quality polyester fibers that are bonded together using a special hot-melt adhesive process. This method creates a strap that is lightweight yet incredibly strong, with the durability to withstand shifting, bumping, and external stress during loading, unloading, and transit.

Unlike twine or natural fiber ropes, which can stretch, fray, or break under pressure, hot melt polyester strapping maintains consistent performance. Its high break strength ensures that bales of cardboard, plastics, textiles, or other recyclables remain securely bound from the point of compression to their final destination. This reliability is particularly important during transportation, where vibrations, stacking, and mechanical handling can easily compromise weaker materials.

Economically, hot melt polyester strapping offers significant cost benefits. Its material efficiency means less strap is required per bale compared to bulkier or lower-strength alternatives. Additionally, the reduced risk of bale breakage during shipping translates into fewer losses, less manual rework, and lower insurance or liability concerns. For recycling facilities and waste processors, these operational savings can add up quickly.

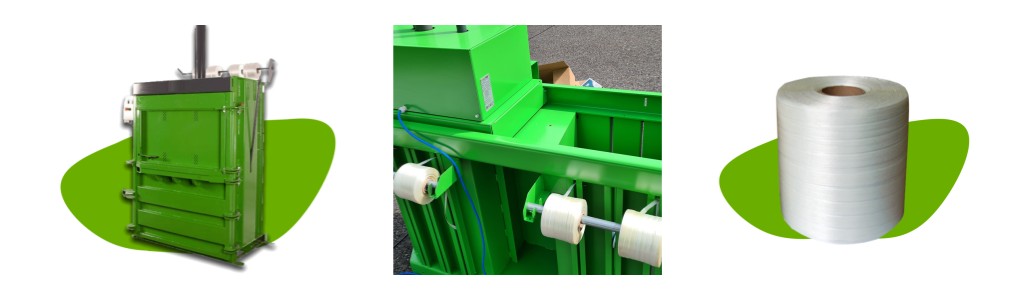

Another major advantage of hot melt polyester strapping is its ease of use. The strap is soft to the touch and safe for workers to handle, with no sharp edges or metal components. It can be applied manually using basic tensioners and buckles, or integrated into semi-automatic and automatic baling systems. The simplicity of application and compatibility with standard tools make it an efficient solution for both large-scale facilities and smaller operations.

From a sustainability perspective, many hot melt strapping products are made from recyclable materials and offer an environmentally friendlier alternative to synthetic rope or single-use plastic twine. Some manufacturers also produce eco-conscious variants designed to meet the needs of green-certified waste management programs.

One of the key performance factors behind hot melt polyester strapping’s success is its ability to absorb shock. Unlike rigid strapping materials, which can snap under sudden tension or movement, hot melt straps exhibit slight flexibility while retaining their core strength. This characteristic allows them to accommodate minor shifts in bale shape or position during handling without compromising the integrity of the bundle.

Industry experts recommend hot melt polyester strapping for applications where high strength and consistent tension are required—especially during transport or export of recyclable materials. For facilities operating in logistics-intensive sectors or regions where road and shipping conditions are less predictable, the added security provided by hot melt straps can prove invaluable.

In summary, hot melt polyester strapping is a modern, high-performance solution that addresses the limitations of traditional twine and rope. It offers superior strength, reliability during transit, ease of handling, and economic efficiency. As recycling and waste transport systems continue to modernize, this innovative material is proving to be a smart choice for companies seeking secure, cost-effective, and sustainable bale packaging solutions.