BSTSTRAP: Hotmelt Strapping – A Reliable Solution for Light to Medium-Duty Applications

In industries that require secure and flexible bundling solutions, hotmelt strapping has become a preferred choice for light to medium-duty applications. This type of strapping offers a perfect balance of strength, durability, and ease of use, making it ideal for packaging, logistics, and material handling. While hotmelt strapping is known for its UV and humidity resistance, it is also important to understand its temperature sensitivity to ensure optimal performance.

What is Hotmelt Strapping?

Hotmelt strapping is made from polyester (PET) or polypropylene (PP) fibers, bonded together using heat and pressure. The result is a high-strength, flexible, and lightweight strapping material that performs well in various industrial applications. Unlike steel or plastic strapping, hotmelt strapping offers a soft texture, reducing the risk of damaging packaged goods while providing excellent shock absorption.

Key Advantages of Hotmelt Strapping

Ideal for Light to Medium-Duty Applications

Hotmelt strapping is designed to handle moderate loads, making it suitable for industries that require secure but flexible bundling. It is commonly used for packaging cartons, securing pallets, and bundling lightweight materials.UV and Humidity Resistance

Unlike some traditional strapping materials, hotmelt strapping is resistant to UV exposure and moisture, ensuring durability in outdoor storage and humid environments. This makes it a great choice for warehousing, shipping, and agricultural applications.Shock Absorption & Flexibility

One of the standout features of hotmelt strapping is its ability to absorb shocks and impacts during transport. It does not snap like steel strapping and adjusts to load movement, providing secure but gentle tension on packaged goods.Soft and Safe to Handle

Unlike steel strapping, which has sharp edges and poses injury risks, hotmelt strapping is smooth and lightweight, making it safe and easy to apply manually or with tensioning tools.

Considerations: Temperature Sensitivity

While hotmelt strapping offers several advantages, it is also sensitive to extreme temperatures.

High Temperatures: Excessive heat can weaken the bonding strength of the fibers, reducing its tensile strength and load-bearing capacity.

Low Temperatures: In extremely cold conditions, hotmelt strapping may become brittle, increasing the risk of breakage under tension.

To maximize performance, BSTSTRAP recommends storing and using hotmelt strapping in moderate temperature conditions and avoiding exposure to extreme heat or cold for prolonged periods.

Common Applications of Hotmelt Strapping

Hotmelt strapping is widely used across multiple industries due to its versatile and cost-effective nature:

Logistics & Warehousing – Securing palletized goods for transport and storage.

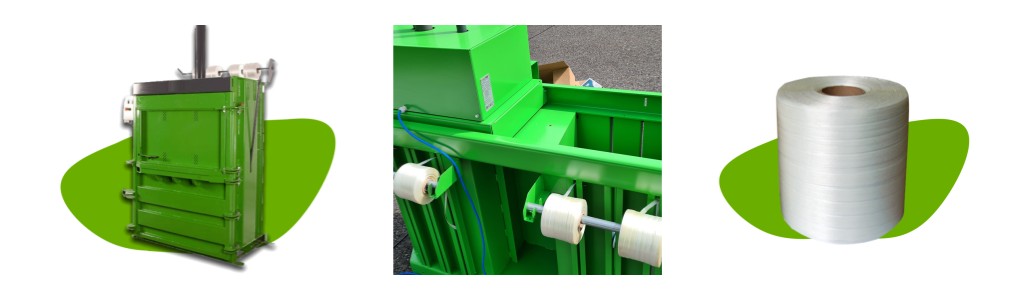

Recycling & Waste Management – Bundling paper, plastic, and other lightweight materials.

Agriculture – Tying hay bales and securing farm produce for transport.

Manufacturing – Packaging cartons, boxes, and fragile products.

BSTSTRAP: Your Trusted Supplier for High-Quality Hotmelt Strapping

As a manufacturer with 16 years of experience in composite and polyester strapping, BSTSTRAP provides premium-quality hotmelt strapping solutions tailored to industry needs. Our products undergo rigorous quality control to ensure optimal strength, durability, and safety.

Why Choose BSTSTRAP Hotmelt Strapping?

✔ High-Quality Bonding – Strong and reliable for light to medium-duty applications.

✔ Weather-Resistant – UV and humidity-resistant for indoor and outdoor use.

✔ Shock Absorption – Reduces impact damage during transport.

✔ Safe & Lightweight – Smooth edges prevent injuries during handling.

✔ Cost-Effective – A more economical option compared to steel and plastic strapping.

For businesses looking for a flexible, reliable, and affordable strapping solution, BSTSTRAP’s hotmelt strapping is the perfect choice. Contact us today to explore our range of strapping products and find the right solution for your packaging and bundling needs.

BSTSTRAP – Strong, Flexible, and Dependable!